Send Time:2019-3-4

An example to appreciate the cable ditch project of Shenzhen Power Supply Bureau of China Southern Power Grid

Source: Cable Recruitment Network Release

This project adopts prefabricated cable ditch and prefabricated cable well assembly technology, and adopts other new technologies and new techniques to realize engineering excellence. Special share to engineering friends reference learning!

Take a look at the construction site first.

1. Point underline: The cable ditch is crossed before excavation, which can effectively control the straightness of the cable ditch.

2. Grass-roots compaction, set up cushion control pile: earth excavation after the foundation compaction, prevent cable groove sinking; After ramming, set up the elevation control pile, which can effectively control the elevation of the cushion.

3. Pad casting: cable groove pad smooth and flat, consistent elevation.

4. Cable well assembly: The cable well adopts block assembly, and the construction efficiency is high.

5. Cable ditch installation: cable ditch with special lifting equipment, safe and stable; After installation, it is straight and beautiful to achieve the desired design effect.

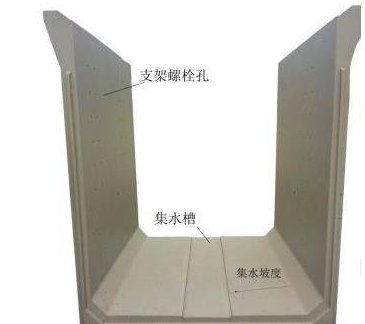

6. Cable support installation: cable groove assembly and installation of cable support can greatly improve the construction efficiency; Stent and cable ditch also use high-strength composite materials, easy to install, beautiful, the use of pre-buried bolt holes, installation no technical difficulty.

7. Filling: Filling of disulfide sealant at the seams can improve the side sealing and integrity of the cable groove.

8. Cover plate installation: Cover plate installation with special cover plate handling tool installation, convenient and safe.

Prefabricated cable ditch

· Light weight, is about 1/3 of the traditional concrete products, easy to lift.

The components have high carrying capacity, good earthquake resistance and good impact resistance.

· Standardization of production, high accuracy, smooth and beautiful inner surface, no need for ash decoration.

:: Low amount of excavation earthwork, easy construction and installation.

:: Not subject to space or time constraints in the area of construction.

· Compared with the concrete concrete cable ditch, the construction period is short and the comprehensive cost is saved.

Prefabricated cable wells

Prefabricated assembly, easy lifting.

The components have high bearing capacity, good earthquake resistance and good impact resistance.

· Standardization of production, high accuracy, smooth and beautiful inner surface, no need for ash decoration.

:: Low amount of excavation earthwork, easy construction and installation.

:: Not subject to space or time constraints in the area of construction.

Shorten the construction progress compared to the cast-in-place cable well.

• Can be used for network inspection wells, work wells, equipment wells, corner wells.

Prefabricated cable groove assembly process

Application of cover plate moving tools: cover plate moving labor saving, effective improvement of construction efficiency and safety.

Application of cable perforation number: Normalize the sequence of cable laying. When failure occurs, it can accurately locate the corresponding number cable for easy maintenance.

Analysis of project bright spots

Cable groove, straight and even.

Easy to install cable bracket, straight and beautiful after installation

Pre-installed fireproof partition, integrated with cable ditch

Prefabricated cable trench cover plate, smooth surface, straight edges, no noise walking

Prefabricated drainage ditch installation is straight, and U-type design is adopted at the bottom of the ditch, which can effectively reduce garbage accumulation.

欢迎咨询

我们会尽快联系您